Favorite Tips About How To Reduce 24v DC 5V

The Fundamental Approaches to Voltage Reduction

Resistive Dividers: Simple, But Often Not Ideal

The simplest, and often first method that comes to mind for voltage reduction, is the humble **resistive voltage divider**. This circuit utilizes two resistors in series across the input voltage, with the output taken across one of the resistors. The voltage is divided proportionally to the resistance values. While incredibly straightforward to implement, resistive dividers have significant limitations when it comes to power delivery and efficiency.

The primary drawback of a resistive divider is its inefficiency. A significant amount of power is dissipated as heat across the resistors, particularly if the output current is high. This means energy is wasted, and the resistors themselves can become quite hot, potentially requiring heat sinks. Furthermore, the output voltage of a resistive divider is highly dependent on the load connected to it. As the load current changes, the output voltage will fluctuate, making it unsuitable for applications requiring a stable and regulated 5V supply.

For these reasons, resistive dividers are generally only suitable for very low-current applications, such as providing a reference voltage for a sensor or a very small signal. They are not recommended for powering any significant load, and certainly not for reliably providing 5V to most digital circuits. Consider them the "quick and dirty" solution, but often not the "right" one.

Despite their limitations, understanding resistive dividers is fundamental to grasping more complex voltage regulation techniques. They serve as a good starting point for conceptualizing how voltage can be manipulated, even if they aren't the star of the show for our 24V to 5V conversion.

12V,9V To 5V DC Step Down Converter Using LM7805 Voltage Regulator DIY

Linear Regulators: The Heat Dissipators

Understanding the L7805 and its Cousins

Stepping up from resistive dividers, we encounter **linear regulators**. These devices are a much more practical solution for our 24V to 5V conversion, particularly for applications requiring a stable output voltage. The most common and easily recognizable linear regulator for 5V output is the L7805 (or its equivalents like the LM7805). This trusty three-terminal device is a workhorse in hobbyist and professional circuits alike.

Linear regulators work by essentially acting as a variable resistor. They "drop" the excess voltage and dissipate it as heat. For example, with a 24V input and a 5V output, the regulator drops 19V. If your device draws 100mA, the regulator will dissipate (24V - 5V) * 0.1A = 1.9 Watts of power as heat. This brings us to the main consideration with linear regulators: heat dissipation.

Due to this heat generation, linear regulators often require a **heat sink**, especially when the voltage difference between input and output is large and the current draw is significant. The larger the voltage difference and the higher the current, the more heat will be generated, and a larger heat sink will be necessary to prevent the regulator from overheating and potentially failing. It's like having a very enthusiastic bouncer who has to expel all the excess energy from the party-goers — he's going to get warm!

Despite the heat, linear regulators offer a very stable and low-noise output voltage, making them ideal for sensitive analog circuits and microcontrollers where voltage ripple could cause problems. They are also relatively inexpensive and simple to implement, requiring only a few external capacitors for stability. However, their inefficiency at large voltage differences remains a key factor to consider.

Switching Regulators: The Efficiency Champions

Buck Converters: Your Best Bet for 24V to 5V

When efficiency is paramount, and especially when dealing with significant voltage differences like our 24V to 5V scenario, **switching regulators** (often called DC-DC converters or switch-mode power supplies — SMPS) are the undisputed champions. Among them, the **buck converter** (or step-down converter) is precisely what we need. Unlike linear regulators that dissipate excess voltage as heat, buck converters work by rapidly switching a component (typically a MOSFET) on and off, storing energy in an inductor, and then releasing it to the output. This "chopping" action, combined with filtering, results in a much more efficient conversion.

The efficiency of a buck converter can typically range from 85% to over 95%, meaning far less energy is wasted as heat. This translates to smaller heat sinks (or no heat sink at all for moderate loads), cooler operation, and a more energy-efficient system overall. If you're running your project off a battery, this efficiency can significantly extend battery life. It's like having a super-efficient sorting machine that only takes what it needs, rather than just throwing away the excess.

Buck converters come in various forms, from integrated circuits that require minimal external components to complete modules that are ready to plug and play. Many readily available modules, often based on chips like the LM2596 or similar, can easily handle the 24V to 5V conversion with impressive efficiency and current capabilities. These modules often include input and output capacitors and sometimes even an output voltage adjustment potentiometer.

While slightly more complex in their internal workings than linear regulators, using pre-built buck converter modules makes them incredibly user-friendly for even novice electronics enthusiasts. Their superior efficiency and reduced heat generation make them the go-to solution for most 24V to 5V DC conversion applications, particularly when power conservation is important or when dealing with higher currents.

Buy DC 9V 12V 24V 36V 48V 72V 84V 120V To 5V 3A Step Down Module Power

Choosing the Right Tool for the Job

Factors to Consider for Your 5V DC Needs

With several methods at our disposal, how do we choose the best way to reduce 24V DC to 5V DC? The answer, as is often the case in engineering, depends on your specific needs and priorities. There's no single "best" solution, but rather the most appropriate one for your application. Let's break down the key factors to consider.

First, consider the **current requirements** of your 5V device. If you're powering a tiny LED or a very low-power sensor that draws only a few milliamps, a linear regulator might suffice, assuming you can manage the minimal heat generated. However, if you're powering a microcontroller with peripherals, an array of LEDs, or a USB device that could draw hundreds of milliamps or even an amp or two, a switching regulator becomes almost mandatory due to its efficiency and lower heat dissipation.

Next, think about **efficiency and heat**. Are you concerned about power waste? Is your project enclosed in a small space where heat buildup is a problem? If so, a buck converter is the clear winner. If you have plenty of airflow and power consumption isn't a critical concern, a linear regulator might be acceptable for lower current draws. Remember, heat is the enemy of electronics!

**Cost and complexity** also play a role. Linear regulators are generally cheaper and simpler to implement if you're building a circuit from scratch. Buck converter modules, while offering superior performance, might have a slightly higher upfront cost, though their long-term benefits often outweigh this. For most users, the ease of use of a pre-built buck module often makes it the most attractive option.

Finally, consider the **output voltage stability and noise**. Linear regulators typically offer a very clean, low-noise output, which is crucial for sensitive analog circuits or audio applications. While buck converters can introduce some ripple, readily available modules are generally well-filtered and perfectly suitable for most digital circuits. If extremely low noise is critical, additional filtering might be considered with a buck converter, or a linear regulator might be preferred if the current allows.

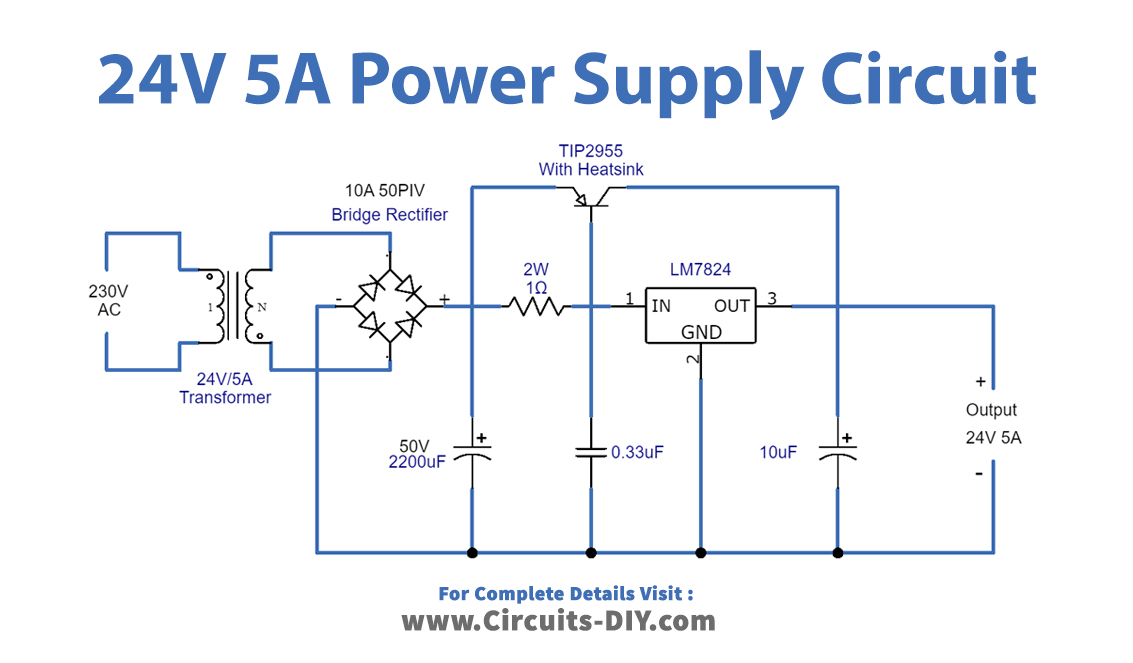

24v To 5v Dc Converter Circuit Diagram

Practical Implementation Tips & Safety First

Making Your Conversion a Success Story

Once you've chosen your preferred method, a few practical tips can help ensure a smooth and safe implementation. Always start by verifying your input voltage. Use a multimeter to confirm that your 24V DC source is indeed providing the expected voltage. This simple step can prevent many headaches down the line.

Pay close attention to **polarity**! DC circuits are unforgiving when it comes to connecting positive to negative incorrectly. Double-check your positive and negative terminals on both the input and output sides of your regulator or converter. A reversed polarity connection can instantly destroy components, often accompanied by a distinct smell of burnt electronics — not a scent you want to become familiar with.

For linear regulators, remember the **heat sink**. If your regulator is getting warm to the touch, it needs a heat sink. The larger the current draw and the voltage difference, the larger the heat sink required. There are formulas and charts available online to help you calculate the appropriate size, but generally, if it's more than mildly warm, it needs more cooling. Don't skimp on this aspect.

When using buck converter modules, many come with an adjustable output voltage. Before connecting your precious 5V device, use a multimeter to verify the output voltage of the module is indeed 5V. Adjust it carefully if necessary. Also, be mindful of the **current rating** of your chosen module; ensure it can supply the maximum current your 5V device will draw. Undersizing the module can lead to overheating and failure. Always err on the side of caution and pick a module with a slightly higher current rating than your expected maximum load.

How To Make 24V 5V Regulator Using 7805 IC YouTube

Frequently Asked Questions

Your Burning 24V to 5V Queries Answered!

Q1: Can I use a simple resistor to reduce 24V to 5V for a small LED?

A1: While technically possible, it's generally not recommended for anything more than a momentary test. Resistors are highly inefficient for voltage reduction, especially with varying loads, and dissipate a lot of power as heat. For an LED, it's better to use a current-limiting resistor calculated for the LED's forward voltage and desired current, rather than trying to drop the entire 19V with just a resistor.

Q2: Why do linear regulators get so hot when converting 24V to 5V?

A2: Linear regulators work by dissipating the excess voltage as heat. In our 24V to 5V example, the regulator has to "drop" 19V. If your device draws, say, 0.5 Amps, the power dissipated as heat will be P = (Vin - Vout) * I = (24V - 5V) * 0.5A = 19V * 0.5A = 9.5 Watts. That's a significant amount of heat, requiring a good heat sink to prevent the regulator from overheating and failing.

Q3: Are buck converters always better than linear regulators for this conversion?

A3: For converting 24V to 5V, especially with any significant current draw, buck converters are almost always the superior choice due to their significantly higher efficiency (less heat, less wasted power). However, linear regulators do offer a very clean, low-noise output, which might be preferred in very sensitive analog audio applications where even slight electrical noise could be problematic, provided the current draw is low enough to manage the heat.